The Efficient PJP Copper Screening Machine redefines precision in cable shielding, offering a high-speed solution for applying copper tape screening to power, control, and communication cables.

| Availability: | |

|---|---|

| Quantity: | |

Leveraging servo-driven precision winding technology, it ensures uniform copper tape coverage (80–100% adjustable) with minimal material waste, critical for effective electromagnetic interference (EMI) and radio frequency interference (RFI) protection. The machine supports variable tape widths (10–50mm) and operates at speeds up to 200 m/min, making it suitable for both small-batch customization and mass production. Its closed-loop tension control system—equipped with load cells and real-time feedback—maintains consistent tape tension (5–50N adjustable), preventing wrinkles, breaks, or uneven overlap during operation.

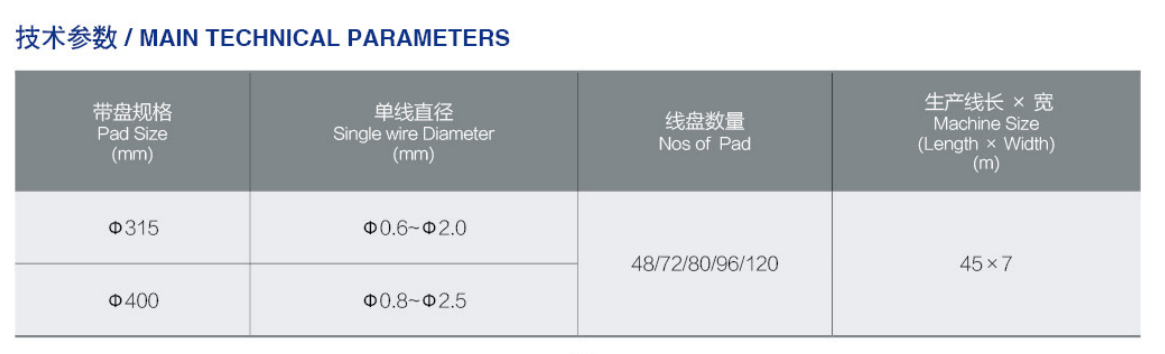

Tape Width Range: 10–50mm (with quick-change tape guides)

Tape Thickness: 0.1–0.5mm (annealed or tinned copper)

Maximum Line Speed: 200 m/min (depending on cable diameter)

Copper Tape Requirements: Conductivity ≥100% IACS, surface roughness Ra ≤0.8μm

Power Supply: 380V 3-phase 50Hz (with 10kVA isolation transformer)

Control System: Mitsubishi FX5 PLC with 7-inch touchscreen and servo drives

Tension Control: Magnetic powder brake with ±1% accuracy

Machine Dimensions: 4m (L) × 2m (W) × 1.8m (H), Weight: 3,500 kg

Power Cables:

Provides EMI shielding for medium-voltage (MV: 10–35kV) and low-voltage (LV: 0.6/1kV) power cables, reducing signal interference and ensuring compliance with IEC 61238-1 (power cables with metallic screens) and ANSI C119.4 (utility cables).

Control Cables:

Critical for industrial control systems (PLC, DCS), where it minimizes crosstalk between signal pairs, ensuring signal integrity in factory automation and process control environments.

Communication Cables:

Enhances performance of data transmission cables (Ethernet Cat 6a, coaxial), reducing attenuation and supporting bandwidth up to 10Gbps for high-speed data transfer.

Automotive Cables:

Used in luxury and electric vehicle wiring (ADAS, infotainment systems), providing RFI shielding to prevent interference with sensitive electronics.

Q: Can the machine handle multiple layers of screening?

A: Yes, it supports dual-layer screening with adjustable overlap (15–50%) between layers, enabling enhanced shielding effectiveness (up to 85dB attenuation at 1GHz) for high-demand applications.

Q: What is the minimum cable diameter it can process?

A: The machine accommodates cables from 3mm to 100mm in diameter, with customizable cable guides and centering systems to ensure uniform tape application across different sizes.

Q: How is copper tape waste minimized?

A: An automatic tape splicing system allows continuous operation during tape roll changes, reducing start/stop waste to less than 0.5%. Additionally, the precision tension control prevents tape breakage and over-stretching.

Leveraging servo-driven precision winding technology, it ensures uniform copper tape coverage (80–100% adjustable) with minimal material waste, critical for effective electromagnetic interference (EMI) and radio frequency interference (RFI) protection. The machine supports variable tape widths (10–50mm) and operates at speeds up to 200 m/min, making it suitable for both small-batch customization and mass production. Its closed-loop tension control system—equipped with load cells and real-time feedback—maintains consistent tape tension (5–50N adjustable), preventing wrinkles, breaks, or uneven overlap during operation.

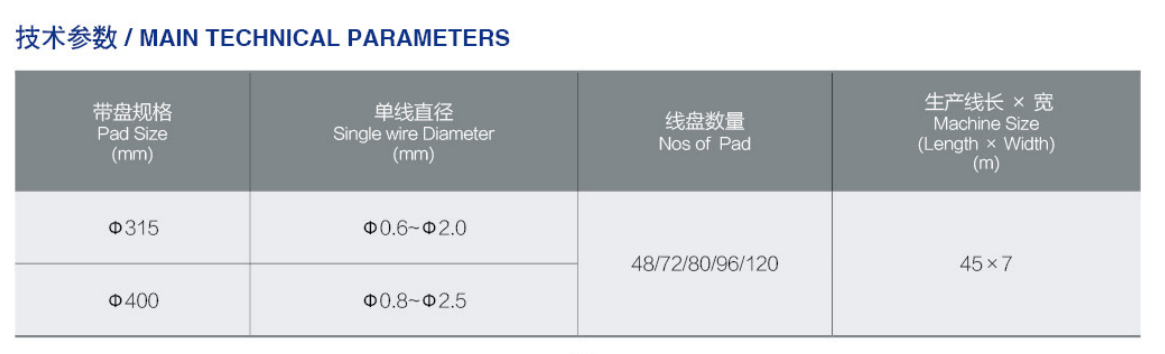

Tape Width Range: 10–50mm (with quick-change tape guides)

Tape Thickness: 0.1–0.5mm (annealed or tinned copper)

Maximum Line Speed: 200 m/min (depending on cable diameter)

Copper Tape Requirements: Conductivity ≥100% IACS, surface roughness Ra ≤0.8μm

Power Supply: 380V 3-phase 50Hz (with 10kVA isolation transformer)

Control System: Mitsubishi FX5 PLC with 7-inch touchscreen and servo drives

Tension Control: Magnetic powder brake with ±1% accuracy

Machine Dimensions: 4m (L) × 2m (W) × 1.8m (H), Weight: 3,500 kg

Power Cables:

Provides EMI shielding for medium-voltage (MV: 10–35kV) and low-voltage (LV: 0.6/1kV) power cables, reducing signal interference and ensuring compliance with IEC 61238-1 (power cables with metallic screens) and ANSI C119.4 (utility cables).

Control Cables:

Critical for industrial control systems (PLC, DCS), where it minimizes crosstalk between signal pairs, ensuring signal integrity in factory automation and process control environments.

Communication Cables:

Enhances performance of data transmission cables (Ethernet Cat 6a, coaxial), reducing attenuation and supporting bandwidth up to 10Gbps for high-speed data transfer.

Automotive Cables:

Used in luxury and electric vehicle wiring (ADAS, infotainment systems), providing RFI shielding to prevent interference with sensitive electronics.

Q: Can the machine handle multiple layers of screening?

A: Yes, it supports dual-layer screening with adjustable overlap (15–50%) between layers, enabling enhanced shielding effectiveness (up to 85dB attenuation at 1GHz) for high-demand applications.

Q: What is the minimum cable diameter it can process?

A: The machine accommodates cables from 3mm to 100mm in diameter, with customizable cable guides and centering systems to ensure uniform tape application across different sizes.

Q: How is copper tape waste minimized?

A: An automatic tape splicing system allows continuous operation during tape roll changes, reducing start/stop waste to less than 0.5%. Additionally, the precision tension control prevents tape breakage and over-stretching.