The KRB Semi-cut Steel Tape Armoring Machine sets a new standard for cable protection, offering a high-precision solution for applying steel tape armor to cables in harsh environments.

| Availability: | |

|---|---|

| Quantity: | |

Its proprietary semi-cutting technology creates overlapping steel strips with controlled longitudinal slits, enhancing mechanical protection while maintaining cable flexibility—a critical balance for applications requiring both durability and installability. The machine supports variable tape widths (15–50mm) and operates at speeds up to 150 m/min, ensuring efficient production of armored cables for underground, submarine, and industrial use.

Tape Width Range: 15–50mm (hot-dip galvanized or stainless steel)

Tape Thickness: 0.3–1.2mm (tensile strength ≥300MPa, elongation ≥10%)

Maximum Line Speed: 150 m/min (depending on cable diameter and tape thickness)

Armoring Overlap: 15–50% adjustable via PLC (ensuring 100% coverage)

Power Supply: 400V 3-phase 50Hz (with 15kVA power supply)

Control System: Mitsubishi iQ-F PLC with touchscreen and servo tension control

Cutting Mechanism: Carbide-tipped semi-cut blades (service life ≥50,000 meters)

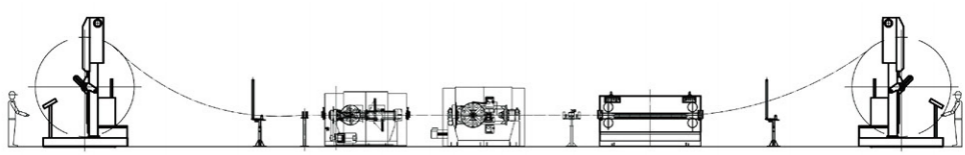

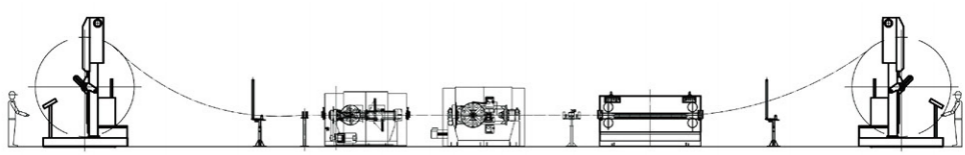

Machine Dimensions: 6m (L) × 3m (W) × 2.2m (H), Weight: 4,500 kg

Power Cables:

Provides mechanical protection for underground (direct burial) and submarine power cables, resisting impact, crushing, and rodent damage (compliant with IEC 60331 and BS EN 50288-4-1).

Mining Cables:

Used in mining equipment cables (shovel, drill, conveyor cables), with armor resisting abrasion from rock and debris (weight loss ≤20mg per Taber abrasion test).

Railway Signaling Cables:

Ensures vibration resistance for signaling and communication cables in railway infrastructure, maintaining integrity under constant train-induced vibrations (tested to EN 50155).

Industrial Cables:

Ideal for heavy-duty machinery cables (crane, robot cables), offering long-term durability in factory and construction environments with frequent bending and mechanical stress.

Q: What is the minimum cable diameter it can armor?

A: The machine processes cables from 10mm to 150mm in diameter, with adjustable cable guides and centering rollers to ensure uniform armor application across different sizes.

Q: How is the steel tape bonded to the cable?

A: The semi-cut design creates interlocking tabs between adjacent strips, forming a continuous armor layer that “grips” the cable sheath without adhesives, ensuring flexibility while preventing armor slippage.

Q: Can it handle multiple armor layers?

A: Yes, the machine supports dual-layer armoring with adjustable overlap between layers (typically 20–30% for inner layer, 30–50% for outer layer), doubling impact resistance for extreme environments.

Q: What maintenance is required for the cutting blades?

A: Carbide-tipped blades require inspection every 5,000 meters of production and replacement every 50,000 meters (or sooner if processing stainless steel tape). The machine includes blade wear sensors that alert operators to replace blades proactively.

Its proprietary semi-cutting technology creates overlapping steel strips with controlled longitudinal slits, enhancing mechanical protection while maintaining cable flexibility—a critical balance for applications requiring both durability and installability. The machine supports variable tape widths (15–50mm) and operates at speeds up to 150 m/min, ensuring efficient production of armored cables for underground, submarine, and industrial use.

Tape Width Range: 15–50mm (hot-dip galvanized or stainless steel)

Tape Thickness: 0.3–1.2mm (tensile strength ≥300MPa, elongation ≥10%)

Maximum Line Speed: 150 m/min (depending on cable diameter and tape thickness)

Armoring Overlap: 15–50% adjustable via PLC (ensuring 100% coverage)

Power Supply: 400V 3-phase 50Hz (with 15kVA power supply)

Control System: Mitsubishi iQ-F PLC with touchscreen and servo tension control

Cutting Mechanism: Carbide-tipped semi-cut blades (service life ≥50,000 meters)

Machine Dimensions: 6m (L) × 3m (W) × 2.2m (H), Weight: 4,500 kg

Power Cables:

Provides mechanical protection for underground (direct burial) and submarine power cables, resisting impact, crushing, and rodent damage (compliant with IEC 60331 and BS EN 50288-4-1).

Mining Cables:

Used in mining equipment cables (shovel, drill, conveyor cables), with armor resisting abrasion from rock and debris (weight loss ≤20mg per Taber abrasion test).

Railway Signaling Cables:

Ensures vibration resistance for signaling and communication cables in railway infrastructure, maintaining integrity under constant train-induced vibrations (tested to EN 50155).

Industrial Cables:

Ideal for heavy-duty machinery cables (crane, robot cables), offering long-term durability in factory and construction environments with frequent bending and mechanical stress.

Q: What is the minimum cable diameter it can armor?

A: The machine processes cables from 10mm to 150mm in diameter, with adjustable cable guides and centering rollers to ensure uniform armor application across different sizes.

Q: How is the steel tape bonded to the cable?

A: The semi-cut design creates interlocking tabs between adjacent strips, forming a continuous armor layer that “grips” the cable sheath without adhesives, ensuring flexibility while preventing armor slippage.

Q: Can it handle multiple armor layers?

A: Yes, the machine supports dual-layer armoring with adjustable overlap between layers (typically 20–30% for inner layer, 30–50% for outer layer), doubling impact resistance for extreme environments.

Q: What maintenance is required for the cutting blades?

A: Carbide-tipped blades require inspection every 5,000 meters of production and replacement every 50,000 meters (or sooner if processing stainless steel tape). The machine includes blade wear sensors that alert operators to replace blades proactively.