The Pneumatic TQDV Caterpillar for Cable Hauling represents a breakthrough in traction system technology, engineered to handle heavy-duty cable pulling across manufacturing, construction, and infrastructure projects.

| Availability: | |

|---|---|

| Quantity: | |

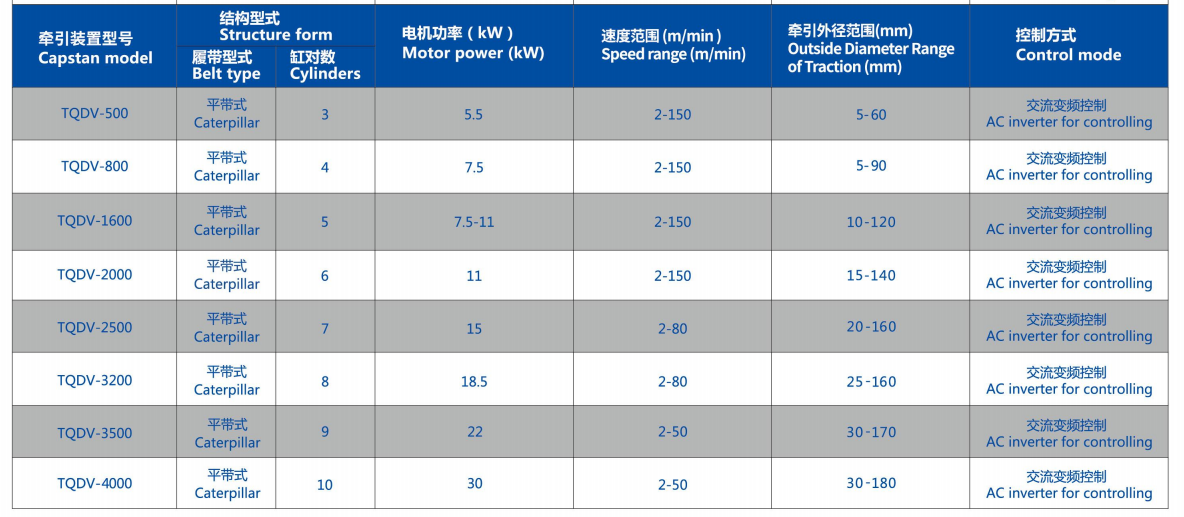

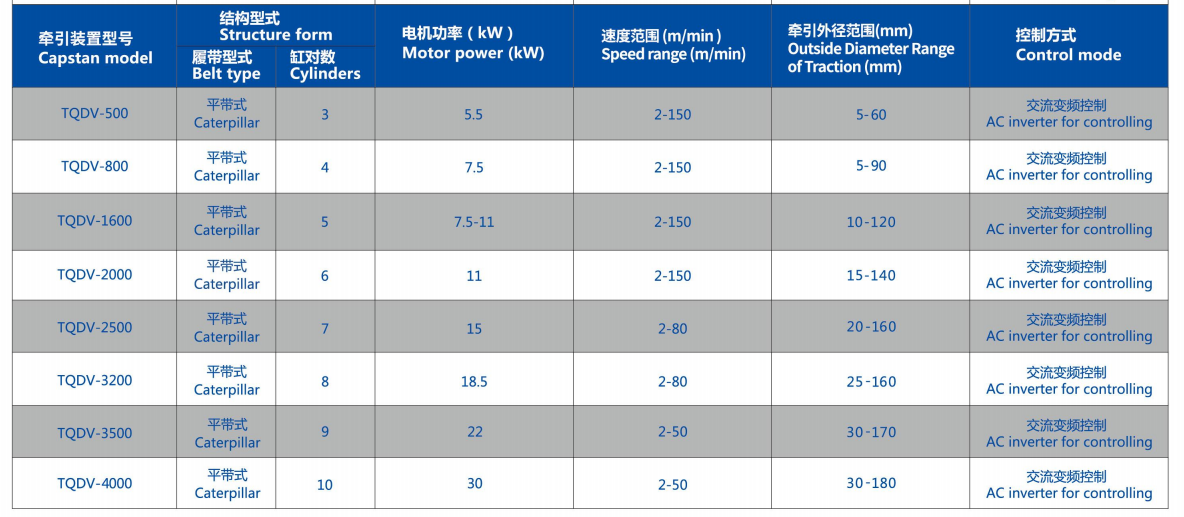

Its proprietary pneumatic compression system delivers a precise balance of grip and gentleness, ensuring firm traction without causing cable deformation—a critical advantage for delicate or high-value cables. With a maximum traction force of 15,000 kg and variable speed control (2-150 m/min), it adapts seamlessly to diverse cable types, from lightweight fiber optics to thick-armored power cables. Field-proven in over 500 installations worldwide, this system reduces cable damage rates by 40% compared to mechanical traction methods, while its modular design enables easy integration into existing production lines.

Frame: Heavy-duty steel plate construction (12-20 mm thickness) with anti-rust epoxy coating (≥80 μm thickness), tested to withstand 1,000 hours of salt spray exposure without corrosion.

Tracks: 3-10 pairs of polyurethane-coated rollers with Shore A hardness of 85±5, providing non-slip grip while preventing cable surface marring. Roller spacing is adjustable in 5 mm increments.

Pneumatic System: Equipped with precision pressure regulators and flow control valves, supporting 0.1-1.0 MPa air pressure for stepless clamping force adjustment. Includes air filtration and drying unit to prevent moisture-related damage.

Cable Diameter Range: Versatile handling of 3.0-180 mm cables, with quick-change roller sets available for diameters outside this range (1-3 mm or 150-200 mm).

Line Speed: 2-150 m/min with frequency conversion control, featuring soft start/stop functionality to avoid cable shock loading. Speed accuracy is ±1% of set value.

Motor Power: 3-37 kW AC motor with IP55 protection rating, delivering high torque output even at low speeds. Energy recovery system reduces power consumption by 15% during deceleration.

Emergency Stop: Dual-channel emergency stop system with redundant relays, achieving instant shutdown within 0.3 seconds in case of overload, misalignment, or operator intervention.

Infrared Meter Counter: High-precision optical encoder with ±0.1% length measurement accuracy, providing real-time monitoring of cable length, speed, and accumulated footage.

Overload Protection: Built-in load cells trigger automatic pressure reduction when traction force exceeds 110% of set value, preventing cable stretching or breakage.

Power Grid Construction

Efficiently pulls high-voltage transmission cables (110 kV-500 kV) during underground and overhead installation, reducing manual labor requirements by 60% compared to traditional winch systems.

Integrates with cable laying machines to maintain consistent tension, minimizing sagging and ensuring accurate conductor positioning.

Submarine Cable Laying

Withstands harsh marine environments (IP66 protection) and provides precise tension control (±2% accuracy) during deep-sea cable deployment, critical for preventing water ingress in armored cables.

Manufacturing Lines

Seamlessly integrates with extrusion lines, stranding machines, and armoring lines for continuous production, supporting JIT manufacturing through synchronized speed control with upstream/downstream equipment.

Mining and Heavy Industry

Handles thick, abrasive cables used in mining equipment (e.g., shovel cables, hoist cables) with reinforced rollers and enhanced dust protection, reducing maintenance intervals in dusty environments.

Q: Can the caterpillar handle multiple cable diameters without reconfiguration?

A: Yes, the adjustable pneumatic system automatically compensates for diameter variations within a 3:1 range (e.g., 10-30 mm) without tooling changes. For larger diameter ranges, quick-change roller sets can be swapped in under 30 minutes.

Q: What is the maintenance schedule for optimal performance?

A: Lubricate roller bearings with lithium-based grease every 500 operating hours, inspect pneumatic seals quarterly for wear, and calibrate pressure sensors annually. Replace polyurethane roller coatings when surface hardness drops below Shore A 75.

Q: Is it compatible with automated production systems?

A: Yes, it supports PLC integration via Profibus, Ethernet/IP, or Modbus protocols, enabling synchronized operation with upstream and downstream equipment. Includes analog and digital I/O ports for custom automation logic.

Q: What is the maximum incline it can handle during cable pulling?

A: When properly anchored with the optional stabilization kit, it can operate efficiently on slopes up to 30 degrees while maintaining consistent traction force and preventing slippage.

Its proprietary pneumatic compression system delivers a precise balance of grip and gentleness, ensuring firm traction without causing cable deformation—a critical advantage for delicate or high-value cables. With a maximum traction force of 15,000 kg and variable speed control (2-150 m/min), it adapts seamlessly to diverse cable types, from lightweight fiber optics to thick-armored power cables. Field-proven in over 500 installations worldwide, this system reduces cable damage rates by 40% compared to mechanical traction methods, while its modular design enables easy integration into existing production lines.

Frame: Heavy-duty steel plate construction (12-20 mm thickness) with anti-rust epoxy coating (≥80 μm thickness), tested to withstand 1,000 hours of salt spray exposure without corrosion.

Tracks: 3-10 pairs of polyurethane-coated rollers with Shore A hardness of 85±5, providing non-slip grip while preventing cable surface marring. Roller spacing is adjustable in 5 mm increments.

Pneumatic System: Equipped with precision pressure regulators and flow control valves, supporting 0.1-1.0 MPa air pressure for stepless clamping force adjustment. Includes air filtration and drying unit to prevent moisture-related damage.

Cable Diameter Range: Versatile handling of 3.0-180 mm cables, with quick-change roller sets available for diameters outside this range (1-3 mm or 150-200 mm).

Line Speed: 2-150 m/min with frequency conversion control, featuring soft start/stop functionality to avoid cable shock loading. Speed accuracy is ±1% of set value.

Motor Power: 3-37 kW AC motor with IP55 protection rating, delivering high torque output even at low speeds. Energy recovery system reduces power consumption by 15% during deceleration.

Emergency Stop: Dual-channel emergency stop system with redundant relays, achieving instant shutdown within 0.3 seconds in case of overload, misalignment, or operator intervention.

Infrared Meter Counter: High-precision optical encoder with ±0.1% length measurement accuracy, providing real-time monitoring of cable length, speed, and accumulated footage.

Overload Protection: Built-in load cells trigger automatic pressure reduction when traction force exceeds 110% of set value, preventing cable stretching or breakage.

Power Grid Construction

Efficiently pulls high-voltage transmission cables (110 kV-500 kV) during underground and overhead installation, reducing manual labor requirements by 60% compared to traditional winch systems.

Integrates with cable laying machines to maintain consistent tension, minimizing sagging and ensuring accurate conductor positioning.

Submarine Cable Laying

Withstands harsh marine environments (IP66 protection) and provides precise tension control (±2% accuracy) during deep-sea cable deployment, critical for preventing water ingress in armored cables.

Manufacturing Lines

Seamlessly integrates with extrusion lines, stranding machines, and armoring lines for continuous production, supporting JIT manufacturing through synchronized speed control with upstream/downstream equipment.

Mining and Heavy Industry

Handles thick, abrasive cables used in mining equipment (e.g., shovel cables, hoist cables) with reinforced rollers and enhanced dust protection, reducing maintenance intervals in dusty environments.

Q: Can the caterpillar handle multiple cable diameters without reconfiguration?

A: Yes, the adjustable pneumatic system automatically compensates for diameter variations within a 3:1 range (e.g., 10-30 mm) without tooling changes. For larger diameter ranges, quick-change roller sets can be swapped in under 30 minutes.

Q: What is the maintenance schedule for optimal performance?

A: Lubricate roller bearings with lithium-based grease every 500 operating hours, inspect pneumatic seals quarterly for wear, and calibrate pressure sensors annually. Replace polyurethane roller coatings when surface hardness drops below Shore A 75.

Q: Is it compatible with automated production systems?

A: Yes, it supports PLC integration via Profibus, Ethernet/IP, or Modbus protocols, enabling synchronized operation with upstream and downstream equipment. Includes analog and digital I/O ports for custom automation logic.

Q: What is the maximum incline it can handle during cable pulling?

A: When properly anchored with the optional stabilization kit, it can operate efficiently on slopes up to 30 degrees while maintaining consistent traction force and preventing slippage.