The Silicone Rubber Extruding Line for Wire Insulation is engineered to address the high-temperature and high-reliability demands of modern wire manufacturing across automotive, aerospace, and medical sectors. At its heart is platinum-catalyzed vulcanization (Pt-V) technology, a clean, efficient process that delivers uniform cross-linking of silicone rubber without the toxic byproducts of peroxide curing. This results in insulation with excellent dielectric properties (dielectric constant ≤3.0, dissipation factor ≤0.001) and long-term thermal stability—capable of continuous operation at 200°C and intermittent exposure to 250°C.

| Availability: | |

|---|---|

| Quantity: | |

Its precision metering pump achieves ±1% dosing accuracy, ensuring consistent silicone rubber delivery to the extrusion die, while the multi-layer extrusion die enables production of ultra-thin insulation layers (0.1-0.5 mm) with exceptional concentricity (±0.02 mm). Designed for rapid changeovers, the line features quick-change tooling that reduces downtime between 1.0-6.0 mm wire diameters by 30% compared to conventional systems. Whether producing automotive engine compartment wires, avionics cables, or medical device leads, this line ensures consistent quality, compliance with strict industry standards, and maximum production efficiency.

Cross-linking Method: Hot-air vulcanization (HAV) with PID-controlled ovens maintaining 180-250°C (adjustable in 1°C increments). Vulcanization time is precisely controlled via line speed, with DSC analysis validating cross-linking completeness (>95% gel content).

Material Compatibility: Handles both liquid silicone rubber (LSR) (viscosity 100-10,000 cSt) and high-consistency rubber (HCR) (Mooney viscosity 40-80), with dedicated feeding systems for each material type. Complies with UL 94 V-0 flame rating and RoHS 2.0 (2011/65/EU) for restricted substances.

Line Speed: Variable from 5-100 m/min via a servo-driven capstan with torque feedback, ensuring low tension (5-50 N) to prevent stretching of delicate wires while maintaining stable production.

Extruder: φ45-φ65 mm twin-screw extruder with L/D ratio 16:1 and intermeshing screws for superior mixing. The self-wiping design prevents material buildup, delivering 50-200 kg/h output with consistent melt pressure (±5% tolerance).

Die Design: Coaxial multi-layer die enabling insulation+jacket co-extrusion in a single pass, with adjustable concentricity via precision micrometers. Die lips are chrome-plated for wear resistance and easy cleaning.

Cooling System: Combination water spray + air cooling station reduces post-vulcanization temperature from 200°C to ≤50°C, with adjustable water flow (10-30 L/min) and air pressure (0.2-0.5 MPa) to prevent thermal shock.

PLC+HMI Interface: 12-inch touchscreen displays real-time data on die pressure (0-20 MPa), vulcanization time (1-10 seconds), and insulation thickness (measured via laser micrometer with ±0.01 mm accuracy). Stores 50+ production recipes for quick recall.

Safety Features: Automatic shutdown triggers at over-temperature (≥280°C) or material flow interruption (detected via pressure sensors), with emergency stop buttons at multiple stations and interlocked oven doors.

Automotive Industry

Manufactures 150-200°C rated wires for engine compartments, transmission systems, and EV battery connections, meeting ISO 6722-1 (Class B/C) and VW LV 216 standards for temperature resistance and vibration durability.

Produces multi-core cables for ADAS (Advanced Driver Assistance Systems) with low EMI/RFI interference (shielding effectiveness ≥85 dB at 1 GHz) and tight dimensional tolerances.

Aerospace & Defense

Produces lightweight silicone-insulated cables for aircraft interiors and avionics, with flame resistance (FAR 25.853, 60-second vertical burn test) and salt fog resistance (ASTM B117, 500-hour exposure with no corrosion).

Supports manufacturing of military-spec cables with chemical resistance to fuels, hydraulic fluids, and cleaning agents per MIL-W-22759/34.

Medical Devices

Processes biocompatible silicone wires (ISO 10993-5 cytotoxicity compliant) for pacemakers, defibrillators, and endoscopic tools, ensuring no leachable substances and excellent flexibility.

Enables production of sterilization-resistant cables that withstand repeated autoclaving (134°C, 3 bar, 30 minutes) without performance degradation.

Industrial Robotics

Creates flexible cables for robotic arms and automated machinery, with 10 million bend cycles durability (ASTM D2176, 10× cable diameter bend radius) and resistance to oils and coolants (ISO 6722-2).

Q: What types of silicone rubber can this line process?

A: It handles both LSR (liquid silicone rubber) with viscosity 100-10,000 cSt and HCR (high-consistency rubber) with Mooney viscosity 40-80. Custom formulations for specialized applications (e.g., low-outgassing, high dielectric strength) can be accommodated with minor process adjustments.

Q: How does the Pt-V technology improve product quality?

A: Platinum-catalyzed vulcanization eliminates post-curing steps required for peroxide systems, reducing production time by 50%. It also reduces volatile organic compounds (VOCs) by 90% and eliminates corrosive byproducts, resulting in cleaner insulation with better dielectric properties.

Q: Can it integrate with existing wire drawing machines?

A: Yes, its universal capstan interface with adjustable speed synchronization supports seamless integration with most wire drawing machines handling 1.0-6.0 mm wire diameters. The line includes tension control feedback to match upstream processing speeds.

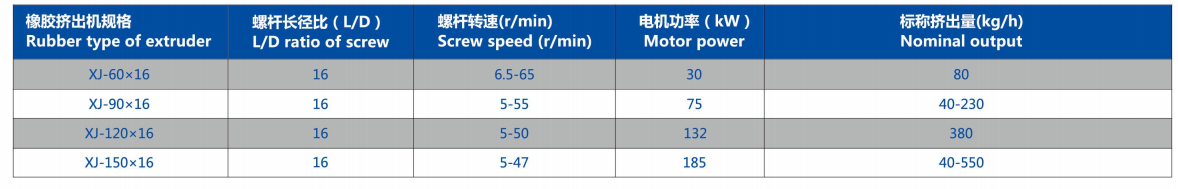

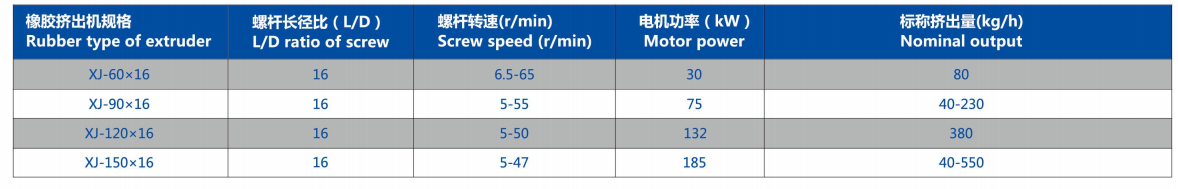

Technical Parameters

Its precision metering pump achieves ±1% dosing accuracy, ensuring consistent silicone rubber delivery to the extrusion die, while the multi-layer extrusion die enables production of ultra-thin insulation layers (0.1-0.5 mm) with exceptional concentricity (±0.02 mm). Designed for rapid changeovers, the line features quick-change tooling that reduces downtime between 1.0-6.0 mm wire diameters by 30% compared to conventional systems. Whether producing automotive engine compartment wires, avionics cables, or medical device leads, this line ensures consistent quality, compliance with strict industry standards, and maximum production efficiency.

Cross-linking Method: Hot-air vulcanization (HAV) with PID-controlled ovens maintaining 180-250°C (adjustable in 1°C increments). Vulcanization time is precisely controlled via line speed, with DSC analysis validating cross-linking completeness (>95% gel content).

Material Compatibility: Handles both liquid silicone rubber (LSR) (viscosity 100-10,000 cSt) and high-consistency rubber (HCR) (Mooney viscosity 40-80), with dedicated feeding systems for each material type. Complies with UL 94 V-0 flame rating and RoHS 2.0 (2011/65/EU) for restricted substances.

Line Speed: Variable from 5-100 m/min via a servo-driven capstan with torque feedback, ensuring low tension (5-50 N) to prevent stretching of delicate wires while maintaining stable production.

Extruder: φ45-φ65 mm twin-screw extruder with L/D ratio 16:1 and intermeshing screws for superior mixing. The self-wiping design prevents material buildup, delivering 50-200 kg/h output with consistent melt pressure (±5% tolerance).

Die Design: Coaxial multi-layer die enabling insulation+jacket co-extrusion in a single pass, with adjustable concentricity via precision micrometers. Die lips are chrome-plated for wear resistance and easy cleaning.

Cooling System: Combination water spray + air cooling station reduces post-vulcanization temperature from 200°C to ≤50°C, with adjustable water flow (10-30 L/min) and air pressure (0.2-0.5 MPa) to prevent thermal shock.

PLC+HMI Interface: 12-inch touchscreen displays real-time data on die pressure (0-20 MPa), vulcanization time (1-10 seconds), and insulation thickness (measured via laser micrometer with ±0.01 mm accuracy). Stores 50+ production recipes for quick recall.

Safety Features: Automatic shutdown triggers at over-temperature (≥280°C) or material flow interruption (detected via pressure sensors), with emergency stop buttons at multiple stations and interlocked oven doors.

Automotive Industry

Manufactures 150-200°C rated wires for engine compartments, transmission systems, and EV battery connections, meeting ISO 6722-1 (Class B/C) and VW LV 216 standards for temperature resistance and vibration durability.

Produces multi-core cables for ADAS (Advanced Driver Assistance Systems) with low EMI/RFI interference (shielding effectiveness ≥85 dB at 1 GHz) and tight dimensional tolerances.

Aerospace & Defense

Produces lightweight silicone-insulated cables for aircraft interiors and avionics, with flame resistance (FAR 25.853, 60-second vertical burn test) and salt fog resistance (ASTM B117, 500-hour exposure with no corrosion).

Supports manufacturing of military-spec cables with chemical resistance to fuels, hydraulic fluids, and cleaning agents per MIL-W-22759/34.

Medical Devices

Processes biocompatible silicone wires (ISO 10993-5 cytotoxicity compliant) for pacemakers, defibrillators, and endoscopic tools, ensuring no leachable substances and excellent flexibility.

Enables production of sterilization-resistant cables that withstand repeated autoclaving (134°C, 3 bar, 30 minutes) without performance degradation.

Industrial Robotics

Creates flexible cables for robotic arms and automated machinery, with 10 million bend cycles durability (ASTM D2176, 10× cable diameter bend radius) and resistance to oils and coolants (ISO 6722-2).

Q: What types of silicone rubber can this line process?

A: It handles both LSR (liquid silicone rubber) with viscosity 100-10,000 cSt and HCR (high-consistency rubber) with Mooney viscosity 40-80. Custom formulations for specialized applications (e.g., low-outgassing, high dielectric strength) can be accommodated with minor process adjustments.

Q: How does the Pt-V technology improve product quality?

A: Platinum-catalyzed vulcanization eliminates post-curing steps required for peroxide systems, reducing production time by 50%. It also reduces volatile organic compounds (VOCs) by 90% and eliminates corrosive byproducts, resulting in cleaner insulation with better dielectric properties.

Q: Can it integrate with existing wire drawing machines?

A: Yes, its universal capstan interface with adjustable speed synchronization supports seamless integration with most wire drawing machines handling 1.0-6.0 mm wire diameters. The line includes tension control feedback to match upstream processing speeds.

Technical Parameters