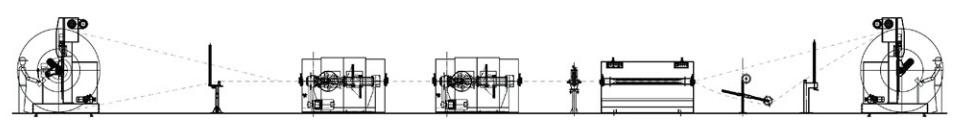

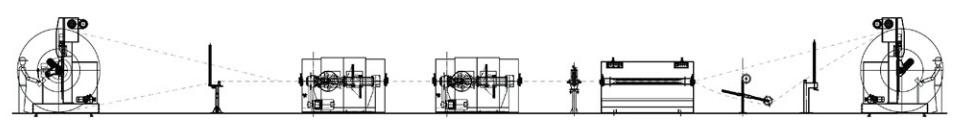

The TRB Wrapping Device is a rugged, industrial-grade solution tailored for power and control cable wrapping, focusing on mechanical reinforcement and electromagnetic shielding.

| Availability: | |

|---|---|

| Quantity: | |

Built to withstand harsh manufacturing environments, it applies copper tape, steel tape, or polypropylene yarn with 80–100% coverage at speeds up to 150 m/min. Its hydraulic tension system delivers consistent force (10–100N) even with thick tapes (up to 1.2mm), ensuring secure bonding without cable deformation. The device’s modular tooling allows quick changes between tape widths (10–50mm), supporting versatile production of armored and shielded cables compliant with IEC 61238 and ANSI C119.4.

Material Compatibility: Copper Tape (0.1–0.5mm thick), Steel Tape (galvanized, 0.3–1.2mm), Polypropylene Yarn (200–1000 denier)

Tape Width: 10–50mm (with tool-free width adjustment)

Tape Thickness: 0.1–1.2mm

Maximum Speed: 150 m/min (for steel tape: 80 m/min due to higher tension requirements)

Wrapping Coverage: 80–100% adjustable (overlap rate 10–50%)

Power Supply: 400V AC, 50Hz (5 kW power consumption)

Control System: Mitsubishi MELSEC iQ-F PLC with 10.1" touchscreen HMI; manual override for setup

Weight: 3,000 kg (heavy-duty steel frame with corrosion-resistant coating)

Footprint: 4m x 2.5m (with integrated safety guarding)

Power Cables:

Wraps tinned copper tape for EMI shielding in medium-voltage (10–35kV) power cables, reducing electromagnetic interference by 90% and complying with IEC 60228 (conductor properties).

Control Cables:

Applies mild steel tape for armoring, enhancing resistance to rodent damage and mechanical impact in industrial control systems (e.g., factory automation), meeting EN 50262 (mechanical protection).

Railway Cables:

Uses UV-stabilized polypropylene yarn for outdoor signaling cables, withstanding 1,000 hours of UV exposure (ISO 4892-3) and temperature cycles (-40°C to 70°C) per EN 50343.

Mining Cables:

Wraps flame-retardant glass tape for underground mining cables, achieving flame propagation index ≤15 (IEC 60332-3) and meeting MSHA (Mine Safety and Health Administration) requirements.

Q: What cable diameter range does this device accommodate?

A: It processes cables from 10mm to 150mm in diameter, with custom guide rollers available for larger sizes up to 200mm.

Q: How does the wrapping secure without adhesives?

The overlapping tape design creates a mechanical interlock (self-locking mechanism) that tightens under cable flexing, eliminating the need for adhesives and reducing material costs.

Q: Can it combine different wrapping materials in a single pass?

Yes, it supports hybrid wrapping (e.g., copper tape for shielding + steel tape for armoring) with synchronized tension control to prevent cable distortion.

Q: What maintenance is required to ensure longevity?

Regular maintenance includes lubricating tension rollers (every 500 hours), calibrating wrap angle sensors (annually), and inspecting hydraulic hoses for leaks (quarterly). The device includes predictive alerts for critical maintenance tasks.

Built to withstand harsh manufacturing environments, it applies copper tape, steel tape, or polypropylene yarn with 80–100% coverage at speeds up to 150 m/min. Its hydraulic tension system delivers consistent force (10–100N) even with thick tapes (up to 1.2mm), ensuring secure bonding without cable deformation. The device’s modular tooling allows quick changes between tape widths (10–50mm), supporting versatile production of armored and shielded cables compliant with IEC 61238 and ANSI C119.4.

Material Compatibility: Copper Tape (0.1–0.5mm thick), Steel Tape (galvanized, 0.3–1.2mm), Polypropylene Yarn (200–1000 denier)

Tape Width: 10–50mm (with tool-free width adjustment)

Tape Thickness: 0.1–1.2mm

Maximum Speed: 150 m/min (for steel tape: 80 m/min due to higher tension requirements)

Wrapping Coverage: 80–100% adjustable (overlap rate 10–50%)

Power Supply: 400V AC, 50Hz (5 kW power consumption)

Control System: Mitsubishi MELSEC iQ-F PLC with 10.1" touchscreen HMI; manual override for setup

Weight: 3,000 kg (heavy-duty steel frame with corrosion-resistant coating)

Footprint: 4m x 2.5m (with integrated safety guarding)

Power Cables:

Wraps tinned copper tape for EMI shielding in medium-voltage (10–35kV) power cables, reducing electromagnetic interference by 90% and complying with IEC 60228 (conductor properties).

Control Cables:

Applies mild steel tape for armoring, enhancing resistance to rodent damage and mechanical impact in industrial control systems (e.g., factory automation), meeting EN 50262 (mechanical protection).

Railway Cables:

Uses UV-stabilized polypropylene yarn for outdoor signaling cables, withstanding 1,000 hours of UV exposure (ISO 4892-3) and temperature cycles (-40°C to 70°C) per EN 50343.

Mining Cables:

Wraps flame-retardant glass tape for underground mining cables, achieving flame propagation index ≤15 (IEC 60332-3) and meeting MSHA (Mine Safety and Health Administration) requirements.

Q: What cable diameter range does this device accommodate?

A: It processes cables from 10mm to 150mm in diameter, with custom guide rollers available for larger sizes up to 200mm.

Q: How does the wrapping secure without adhesives?

The overlapping tape design creates a mechanical interlock (self-locking mechanism) that tightens under cable flexing, eliminating the need for adhesives and reducing material costs.

Q: Can it combine different wrapping materials in a single pass?

Yes, it supports hybrid wrapping (e.g., copper tape for shielding + steel tape for armoring) with synchronized tension control to prevent cable distortion.

Q: What maintenance is required to ensure longevity?

Regular maintenance includes lubricating tension rollers (every 500 hours), calibrating wrap angle sensors (annually), and inspecting hydraulic hoses for leaks (quarterly). The device includes predictive alerts for critical maintenance tasks.